PE Passing Pipe Jacking

The steel wire mesh framework polyethylene composite pipe is a kind of reinforced core layer formed by continuouswinding of coated high strength copper-plated steel wire, and high density plastics (polyethylene) as the basicmaterial. It adopts professional hot melt adhesive (high-performance modifie

Product Introduction

The steel wire mesh framework polyethylene composite pipe is a kind of reinforced core layer formed by continuouswinding of coated high strength copper-plated steel wire, and high density plastics (polyethylene) as the basicmaterial. It adopts professional hot melt adhesive (high-performance modified polyethylene adhesive resin) tocontinuously extrude and compound the pipe on the production line in stages.

It is widely used in long-distance buried water supply. Gas supply pipeline system is the preferred material forreplacing traditional pipes such as steel pipes in China.

It has higher strength, rigidity and impact resistance than the strength of plastic pipe. Double-sided anti-corrosion, with the same corrosion resistance as plastic pipes.

The use temperature increases, the thermal conductivity is low, the external wall does not need thermal insulation in winter and does not condensate in summer.

The inner wall is smooth and scale-free, and the head loss is 30% lower than that of steel tube.

Pipeline connection adopts electro-thermal fusion connection, which has mature technology, strong resistance to axial tension of electro-thermal fusion joint, and many kinds of pipe fitings.

Light weight, convenient transportation and construction, high overall reliability of pipes. Under normal conditions, the service life can reach 50 years.

The hygienic index conforms to GB/T 17292 "Safety Evaluation Index of Domestic Drinking Water Transportationand Distribution Equipment and Protection". The product standard conforms to CF/T189-2007.

The color is usually black. It can also be decided by negotiation between the supplier and the buyer. The inner andouter surfaces of the pipes should be smooth and smooth, allowing for natural shrinkage of small pits andprotrusions, not allowing bubble cracks, decomposition and discoloration and obvious scratches, smooth cutting atboth ends of the pipes.

Municipal Engineering: Urban Water Supply, Heat Network Backwater, Gas and Natural Gas Pipeline.

Chemical engineering: process pipes and discharge pipes for conveying corrosive gases, liquids and solidifiedpowders in acid, alkali,salt manufacturing, petrochemical, fertilizer,pharmaceutical, chemical, rubber and plasticindustries.

Oilfield gas field: oil-bearing sewage, gas field sewage, oil-gas mixture, pipeline for secondary and tertiary oilrecovery gathering and transportation process.

Thermoelectric engineering: process water, backwater transportation, dust removal, waste residue and othertransportation pipelines.

Metallurgical mines: pipes for conveying corrosive media and pulp and tailings in non-ferrous metal smelting.Expressway: buried drainage pipe and cable dredging pipe.

Ocean engineering: sea water transportation, submarine pipelines and optical (electrical) cable conduits, etc.Shipbuilding: Sewage Gate, Drainage Pipe, Ballast Pipe, Ventilation Pipe.

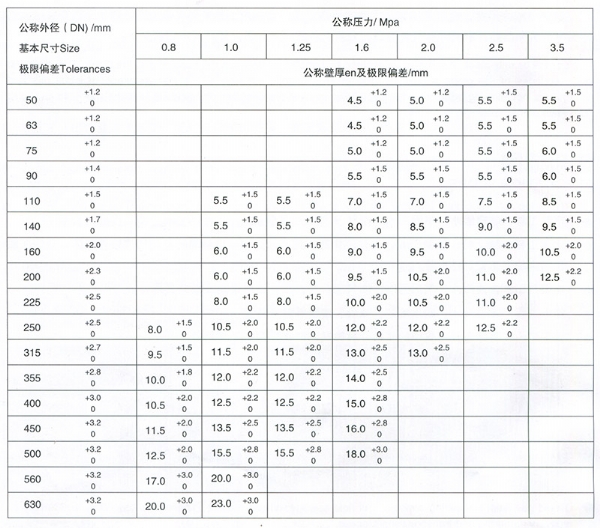

Nominal outer diameter of pipes for water supply and special fluids. Nominal pressure, nominal wall thickness andlimit deviation.

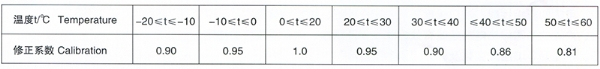

The nominal pressure of pipes should be corrected when conveying medium above or below 20 degrees C. Thespecific data are shown in the table below.

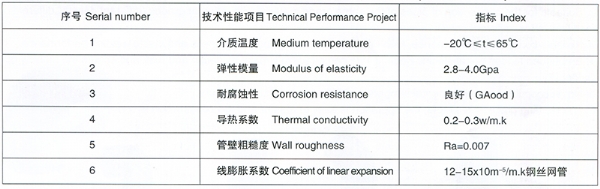

OTHER MAINTECHNICAL PARAMETERS OF STEEL WIRE MESH FRAME PL ASTIC (POLYETHYLENE) COMPOSITE PIPE

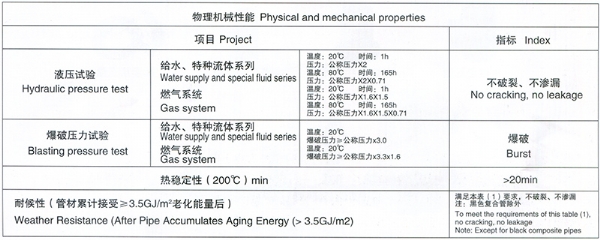

PHYSICAL AND MECHANICAL PROPERTIES (EX-FACTORY INSPECTION ITEMS OF PIPE AND FUSED PIPE FITTINGS)

Product Description:

1. The product implementation standard is: CJ/T189-2007 "Steel mesh skeleton plastic (polyethylene) composite pipe and pipe fittings".

2. Composite pipes of the same specification and different pressure levels have different wire diameters and grid parameters.

3. The nominal pressure is the maximum working pressure of the pipe to transport the water medium at 20°C. If the medium temperature changes, it should be corrected according to the "nominal pressure correction coefficient value".

4. The color of the pipe is generally black, the gas pipe is black or blue, and the black pipe should have a blue color bar.

5. Pipe fixed length: 6m, 12m, can also be determined according to user requirements and transportation conditions

Performance comparison of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe:

First: the production process of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe is different

1. Composite structure. The welded steel skeleton plastic composite pipe is based on ordinary carbon steel wire. Although the steel wire is relatively thick, the tensile strength is only 400Mpa, the process is complicated, and the product quality fluctuates greatly. Steel mesh skeleton plastic (composite pipe, high-strength steel wire (above 1950Mpa) is used as the base material, and the steel wire is wound on the pipe in a 54.7-degree oblique direction, so that the pipe can be axially and The force is uniformly distributed in the circumferential direction, and a high safety factor is adopted when determining the diameter and density of the steel wire.

2. Water channeling on the end face. Welded steel skeleton plastic composite pipe, due to the inevitable gap between the PE material pipe and the steel plate, when the pipe is cut, the end face is sealed, but the seal is easy to fall off when heated with electrofusion pipe fittings. After installation, the medium will enter the gap between the steel plate and the plastic, resulting in a decrease in the pressure bearing capacity of the entire pipeline system. As a result, the pipe will be damaged at low pressure, resulting in the failure of the pipe.

Second: the product standards of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe are different. The steel mesh skeleton plastic composite pipe implements CJ/T189-2007, and the steel skeleton composite pipe implements the CJ/T123-2004 standard;

Third: The steel skeleton composite pipe can be overhead, but the steel mesh composite pipe cannot be overhead.

Prev:Steel Mesh Skeleton Pipeline

Next:PE Mining Pipe