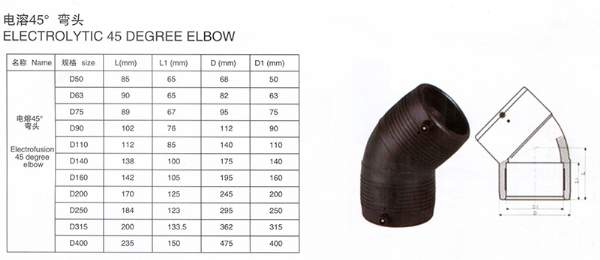

Electrofusion 45° Elbow

PRODUCT CHARACTERISTICS1. It is suitable for the connection of all sizes of pipes of the same SDR series of different materials.2. It is suitable for connecting pipes with different grades (different densities, different melt flow indices, different colors) of the same material of the same grade.3.

Product Introduction

PRODUCT CHARACTERISTICS

1. It is suitable for the connection of all sizes of pipes of the same SDR series of different materials.

2. It is suitable for connecting pipes with different grades (different densities, different melt flow indices, different colors) of the same material of the same grade.

3. Reliable connection performance, high interface strength, good air tightness and stable welding performance.

4. The buried hidden spiral heating wire can effectively resist oxidation and rust, and ensure the stability of weldability.

5. It is not easily affected by environmental temperature changes and human factors.

6. The welding process is simple, the operation is easy to master, and the construction is convenient.

PIPE FITTINGS AND INSTALL ATION

Schematic diagram of piping system connection

CONNECTION PRINCIPLE

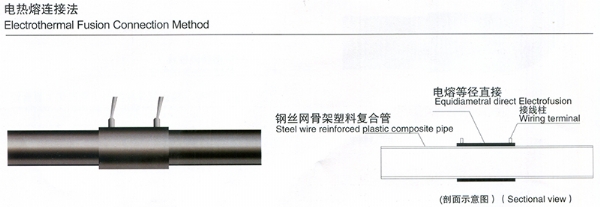

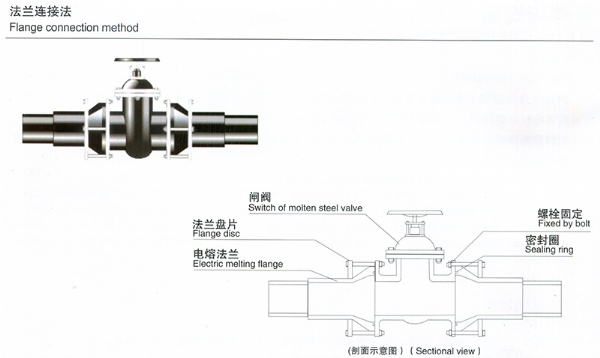

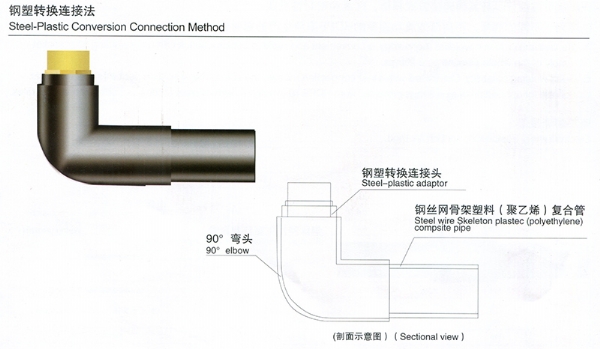

The connection of steel wire mesh framework plastic (polyethylene) composite pipe adopts two ways:

electrothermal fusion and flange connection. The electrothermal fusion connection is to insert the composite pipeinto the electrothermal fusion pipe fttings, and electrify the electric heating wire embedded in the inner surface ofthe pipe fttings to make it hot. The melt expands and flls the gap between the tube and the tube until the outside ofthe tube also produces the melt. The two melts melt and burn together. After cooling and forming, the tube and thetube are closely connected.

Electrofusion 45° Elbow Parameters

CHARACTERISTICS OF PIPE CONNECTION

A. Electrothermal fusion welding technology is convenient and rapid in construction. It can unify welding after socketassembly of the whole pipeline pipe fttings.

B. Good welding relability Compared with other connection modes, the strength and sealing performance are better.

C. Suitable for connection of pipe ftingsg produced from HDPE raw materials with dfferent grades and dfferent melt fow rates.

connection method

Electrothermal fusion connection method

flange connection

Product Description:

1. The product implementation standard is: CJ/T189-2007 "Steel mesh skeleton plastic (polyethylene) composite pipe and pipe fittings".

2. Composite pipes of the same specification and different pressure levels have different wire diameters and grid parameters.

3. The nominal pressure is the maximum working pressure of the pipe to transport the water medium at 20°C. If the medium temperature changes, it should be corrected according to the "nominal pressure correction coefficient value".

4. The color of the pipe is generally black, the gas pipe is black or blue, and the black pipe should have a blue color bar.

5. Pipe fixed length: 6m, 12m, can also be determined according to user requirements and transportation conditions

Performance comparison of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe:

First: the production process of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe is different

1. Composite structure. The welded steel skeleton plastic composite pipe is based on ordinary carbon steel wire. Although the steel wire is relatively thick, the tensile strength is only 400Mpa, the process is complicated, and the product quality fluctuates greatly. Steel mesh skeleton plastic (composite pipe, high-strength steel wire (above 1950Mpa) is used as the base material, and the steel wire is wound on the pipe in a 54.7-degree oblique direction, so that the pipe can be axially and The force is uniformly distributed in the circumferential direction, and a high safety factor is adopted when determining the diameter and density of the steel wire.

2. Water channeling on the end face. Welded steel skeleton plastic composite pipe, due to the inevitable gap between the PE material pipe and the steel plate, when the pipe is cut, the end face is sealed, but the seal is easy to fall off when heated with electrofusion pipe fittings. After installation, the medium will enter the gap between the steel plate and the plastic, resulting in a decrease in the pressure bearing capacity of the entire pipeline system. As a result, the pipe will be damaged at low pressure, resulting in the failure of the pipe.

Second: the product standards of steel mesh skeleton plastic composite pipe and welded steel skeleton plastic composite pipe are different. The steel mesh skeleton plastic composite pipe implements CJ/T189-2007, and the steel skeleton composite pipe implements the CJ/T123-2004 standard;

Third: The steel skeleton composite pipe can be overhead, but the steel mesh composite pipe cannot be overhead.

Next:no more